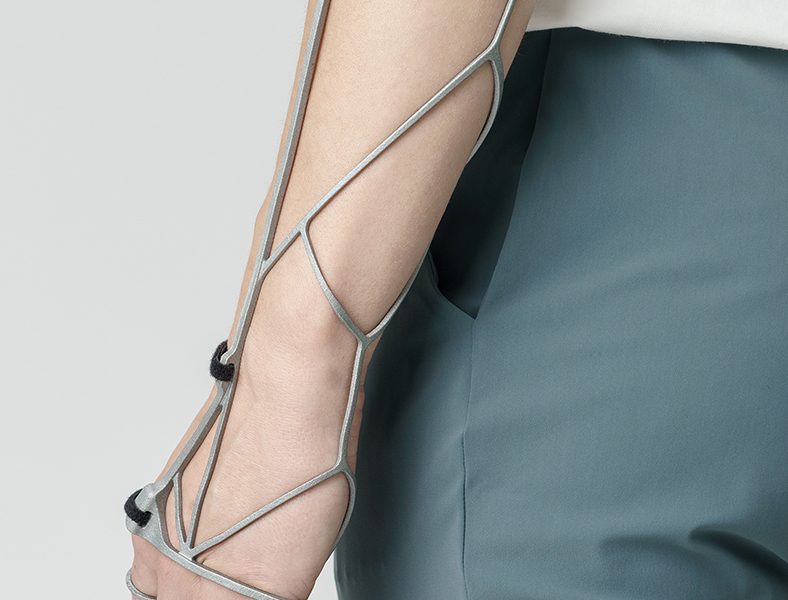

This is the lightest hard brace that weighs only 24 grams but is still extremely tough. The cast is water-resistant, skin-friendly, and can be easily recycled after use. Using 3D-printed aluminium enables for an incredibly open and jewellery-like structure of this brace, allowing for earlier-than-usual physiotherapy, which significantly reduces healing time. Some procedures may even be done at home rather than the clinic, by attaching pre-programmed therapeutic devices to the brace itself. Such structure enables the use of Exo Oro for open bone fractures or post-surgery, when a large surface of naked skin is needed to treat wounds. This 3D-printed cast provides reliable fixation of fractured bones with minimal injury to soft tissues, as it’s modelled by digitally scanning biometric surfaces of the limb. In this way, the splint is optimally formed, and the contact pressure cannot cause skin defects, which aren’t always possible to prevent with plaster casts. This brace model is used to immobilize uncomplicated bone or soft tissue injuries. The Exo Oro arm splint currently costs around 200 euros and is still more expensive than a conventional plastic splint, but production technology is rapidly developing, so its price will soon equal the other splints on the market.